POWERON PROJECTS

POWERON PROJECTSINTRODUCTION:

Of the available energy resources to the industry, Electricity is the only energy which is measured and paid with respect to time in hours like how fast and how much in values namely KVAH, KWH. The machines run from no load to full load in a day; so the proposed panel multi function energy meter can provide to the user what are the no load KWH and load KWH of machine. This Controller will be a tool to monitor machine health / efficiency during routine checks and also to save the under loaded power up to 30%

ENERGY MONITOR CUM CONTROLLER

ENERGY MONITOR CUM CONTROLLER suits to any machine running with varying power consumption from no load to full load during its daily running hours in the batch & continuous process industry and even in the commercial segment where in motor idling is inevitable. By monitoring the loaded & unloaded cumulative power consumption, the above controller will be a tool to assess the machine's health is in Good condition or Average condition or Poor condition.

When we study the macro Specific Energy Consumption of the industry, we look into the energy is spent towards on the two heads of consumption, namely,

• Machine Off- load Energy Consumption that is the Tare Load Consumption

• Machine ON-load Energy Consumption that is the Product Load Consumption.

Taking the case study of a compressor as machine, the compressor daily working efficiency can be studied by this cumulative KWH, KVAH measurement over a period of day, week or month or year and assess the compressor performance over a period of years. Also the same SYSTEM if fitted in two or more compressors in the plant, this can be used to study the relative health monitoring of the compressors, working automatically from no load to full load.

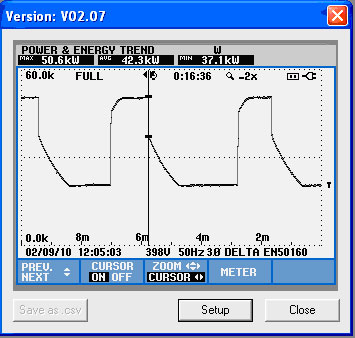

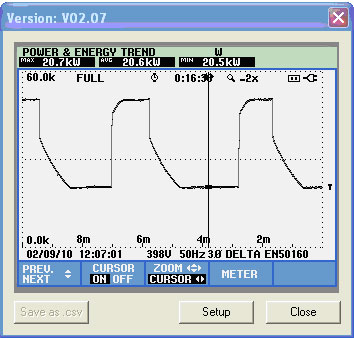

The following data collected from our Energy Audit in an industry, we were monitoring the power waveforms of 45 KW screw compressor (without VFD). The following energy curves show the loading and unloading patterns of the compressor. You will find the cursor tracking the loaded curve as 50.6 KW and in the unloaded curve as 20.7KW.

|

|

| COMPRESSOR LOAD KW = 50.6 KW |

COMPRESSOR UNLOAD KW = 20.7 KW |

So if we intend to have an Energy Monitoring and Controller to address to the above needs of a compressor, then this Compressor Energy Monitor will serve as a daily tool to monitor compressor efficiency. The inbuilt embedded software in the system to include an undercurrent or unload KW setting and the same settable by user during hook up of the above meter. This setting enables instant KW value to switch on to trend Loading KWH & when off to unloading KWH.

• Energy Monitor cum Controller to contain:-

• First page of 3 window displays to show -

• Loaded KWH in top, unloaded KWH - middle, total KWH in bottom window.

• Second page of 3 window display to show -

• Loaded hours, unloaded hours, and total running hours of the compressor.

• Third page of 3 window display to show -

• Loaded units per hour UPH, Unloaded UPH, and Total run UPH

• Further pages to show instant values like KW, KVA, PF, V, a, Hz etc.

• 3 phase volts & currents as Vr, Vy, Vb and Ir, Iy, Ib.

• Also, meter to capture initial KW shoot up and latch display the max KW.

• And if the machine is with VFD, the meter to show loaded KWH, hours, &THD V & I values

Our controller also saves the Under loaded power, during the no load conditions up to 30% (if the load is under 50% in Under load condition)

The sample chart with reference to the BEE guide book indicates the industry's fixed and variable energy consumption over a period as daily, weekly, or monthly or yearly production level. This facilitates the consumer to look into the power consumption above or below the moving averages as the production is varying month to month. This chart analyzes the deviation in macro level.

Why this macro analogy is taken because, this is applicable to the industry in the macro level as well as to each of the machine in the production & utility in the micro level too. When we have a batch of similar machines say like compressors etc, this is an ideal tool towards relative condition monitoring between machine to machine; or between machines working with respect to name plate specs.

There are many similar applications in the industry involving big motors like:-